TRI Commercial Bumpers for dock edges and boat bumpers are manufactured using EPDM rubber formulated to withstand the harshest marine conditions. These bumpers are tough but still provide cushioning and abrasion protection to vessels and facilities. The EPDM compound used in these dock/boat bumpers is very long lasting, and 100% Made in the USA.

TRI produces superior EPDM bumpers that are abrasion and tear resistant while maintaining excellent flexibility at high and low temperatures for continuous cushioning between boat and dock.

All Fenders are made to client specifications and require pre-approval from both TRI and client before product can be manufactured. Techno Rubber Industries uses virgin EPDM rubber for Fenders and Bumpers. Techno Rubber Industries recommends measuring for project prior to purchasing, and ordering at least 10-15% above project minimums to ensure supply for replacement parts, damage, etc.

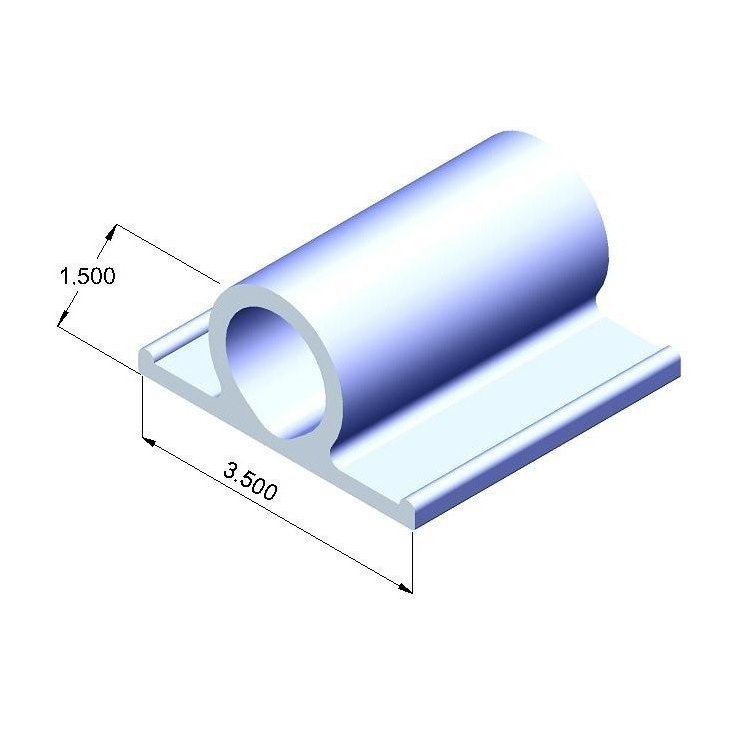

Ship Fender and Ship Bumper Profiles

-

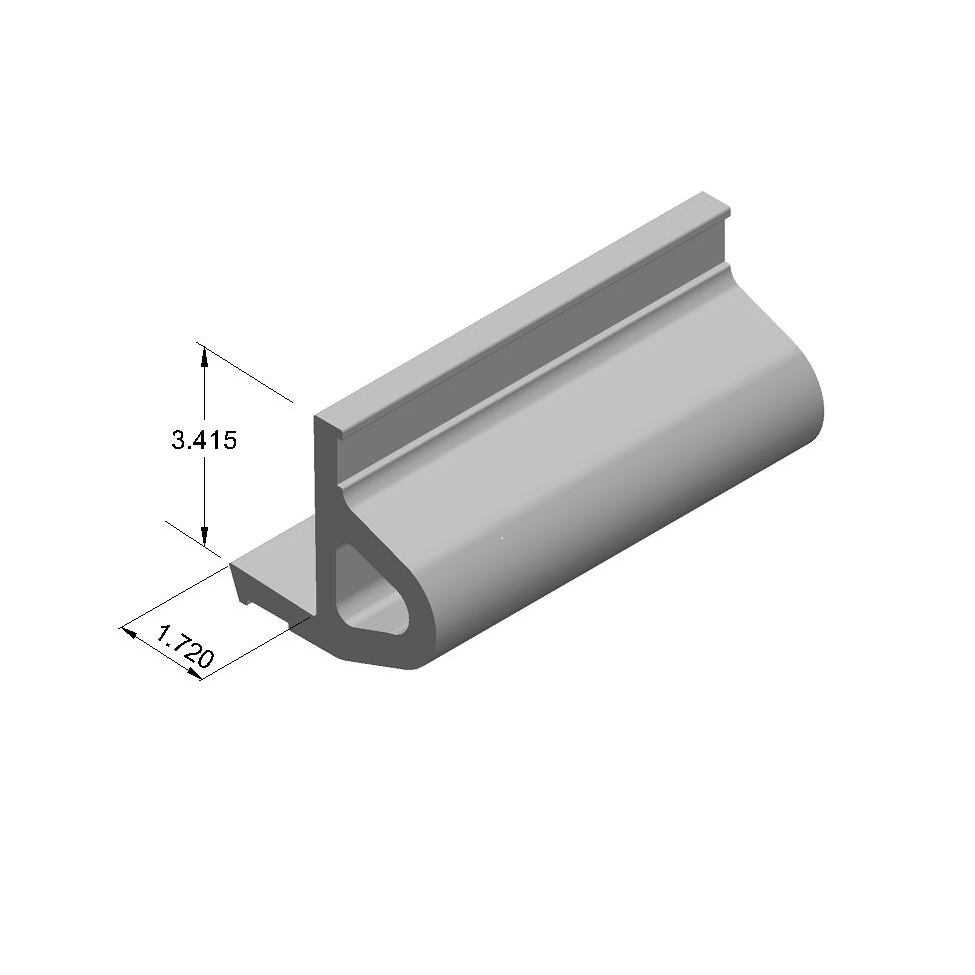

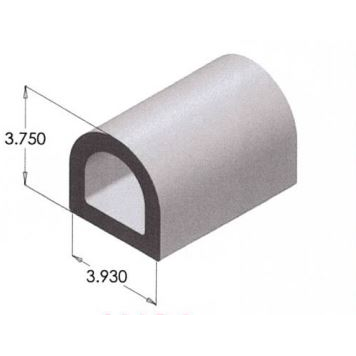

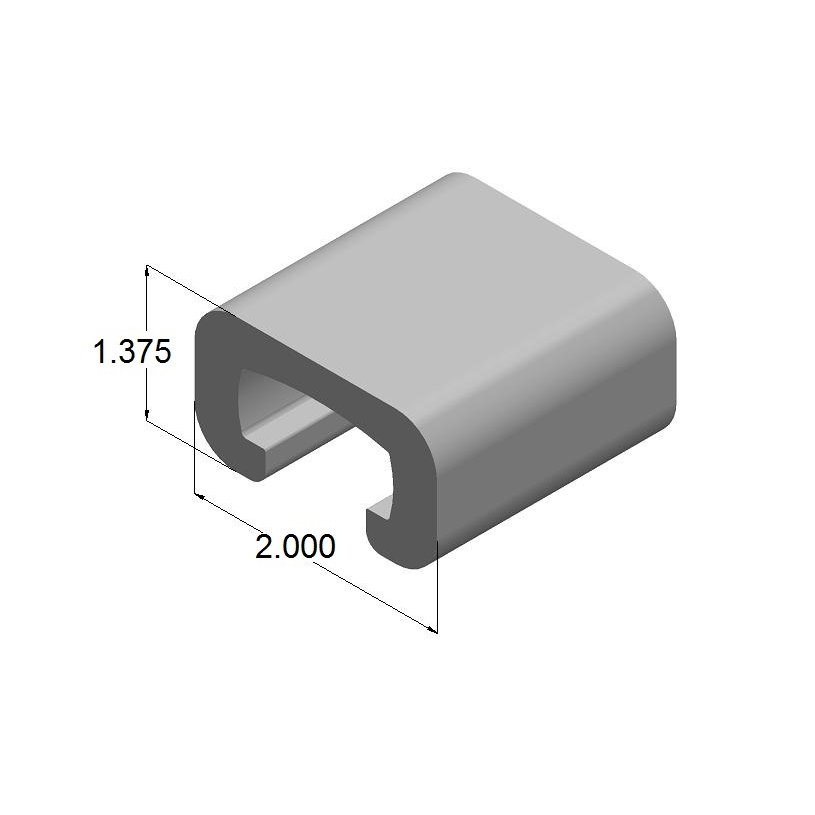

Bumper & Fender 11183

-

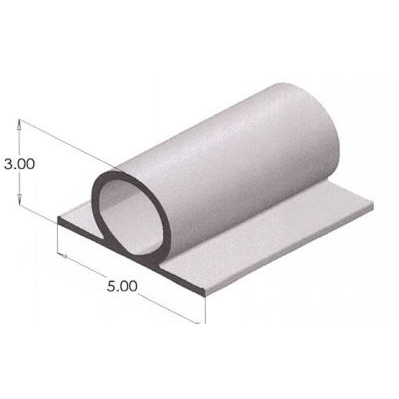

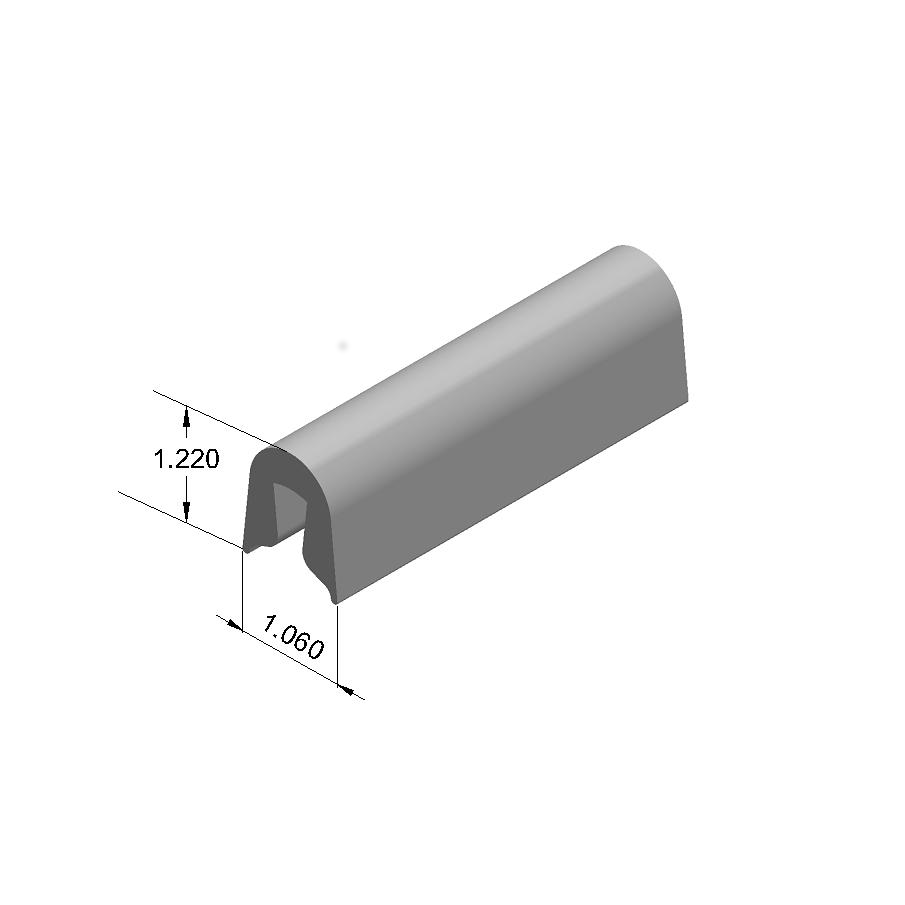

Bumper & Fender 11175

-

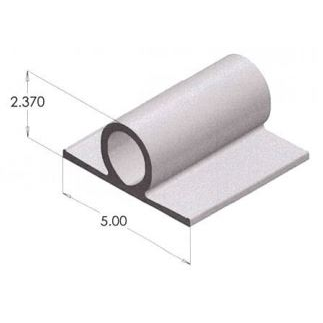

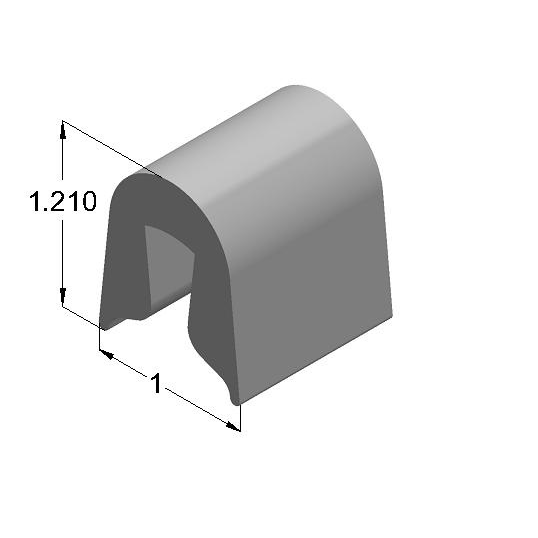

Bumper & Fender 11176

-

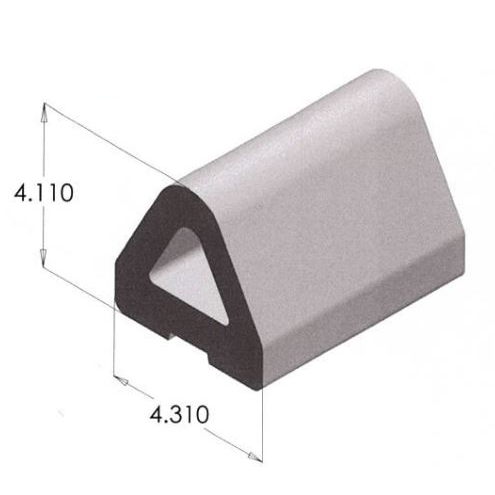

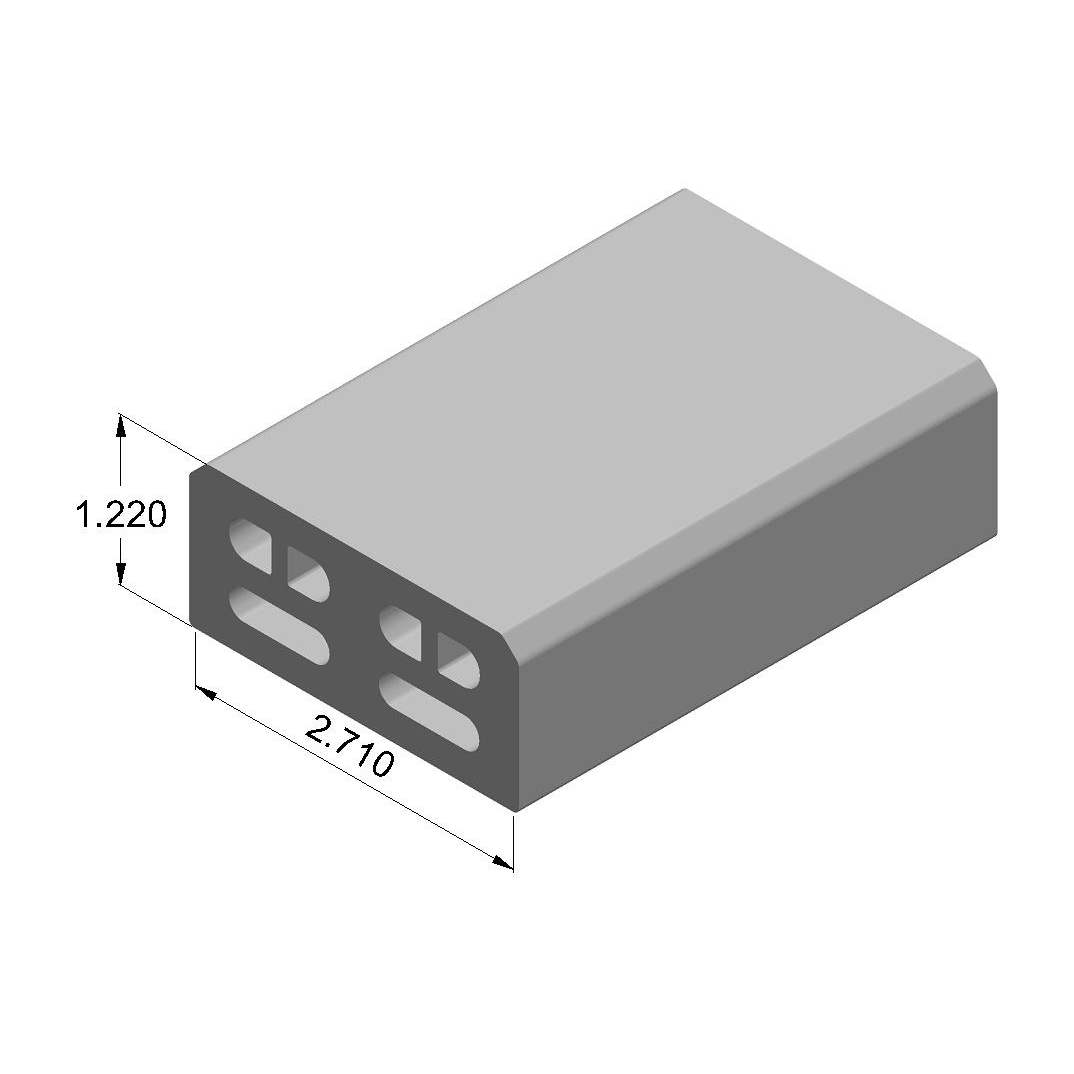

Bumper & Fender 11177

-

Bumper & Fender 11179

-

Bumper & Fender 11180

-

Bumper & Fender 11181

-

Bumper & Fender 11189

-

Bumper & Fender 11190

-

Bumper & Fender 11290

-

Bumper & Fender 11291

-

Bumper & Fender 11293

-

Bumper & Fender 20102

-

Bumper & Fender 20203

-

Bumper & Fender 20212

-

Bumper & Fender 22000

-

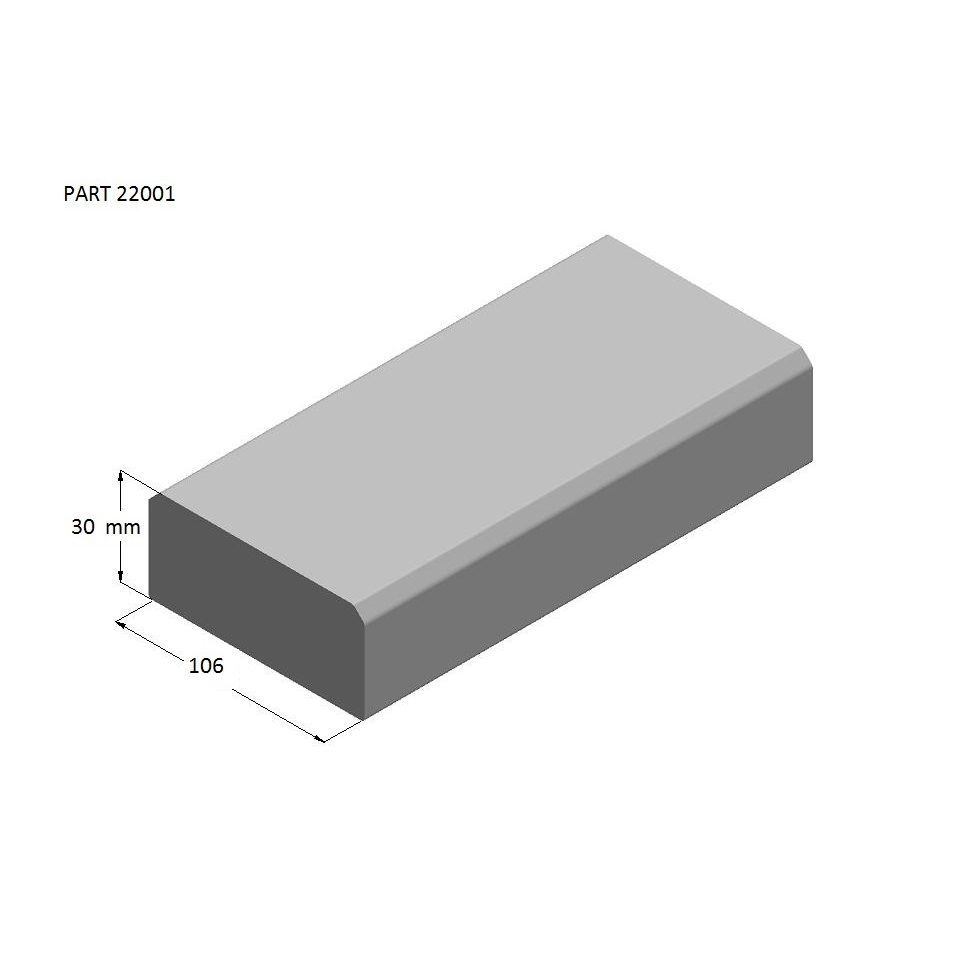

Bumper & Fender 22001

-

Bumper & Fender 22003-22004

-

Bumper & Fender 22005

-

Bumper & Fender 22006

-

Bumper & Fender 30100

-

Bumper & Fender 30101

-

Bumper & Fender 22002

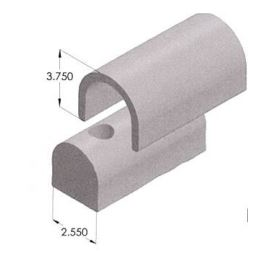

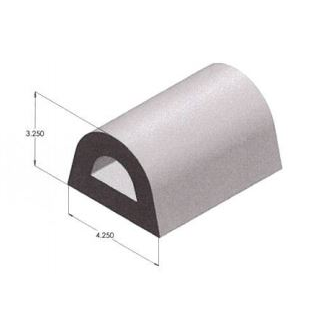

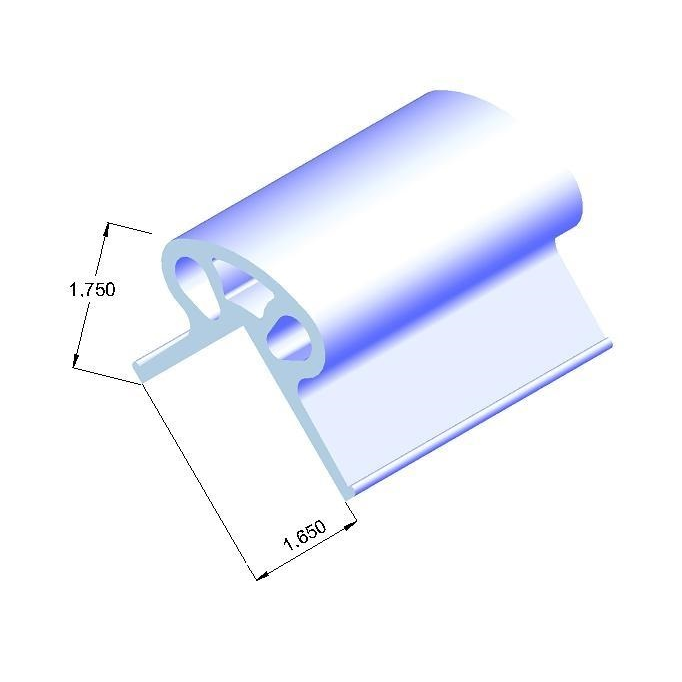

Common Fender Types, including D-Type and Delta Type

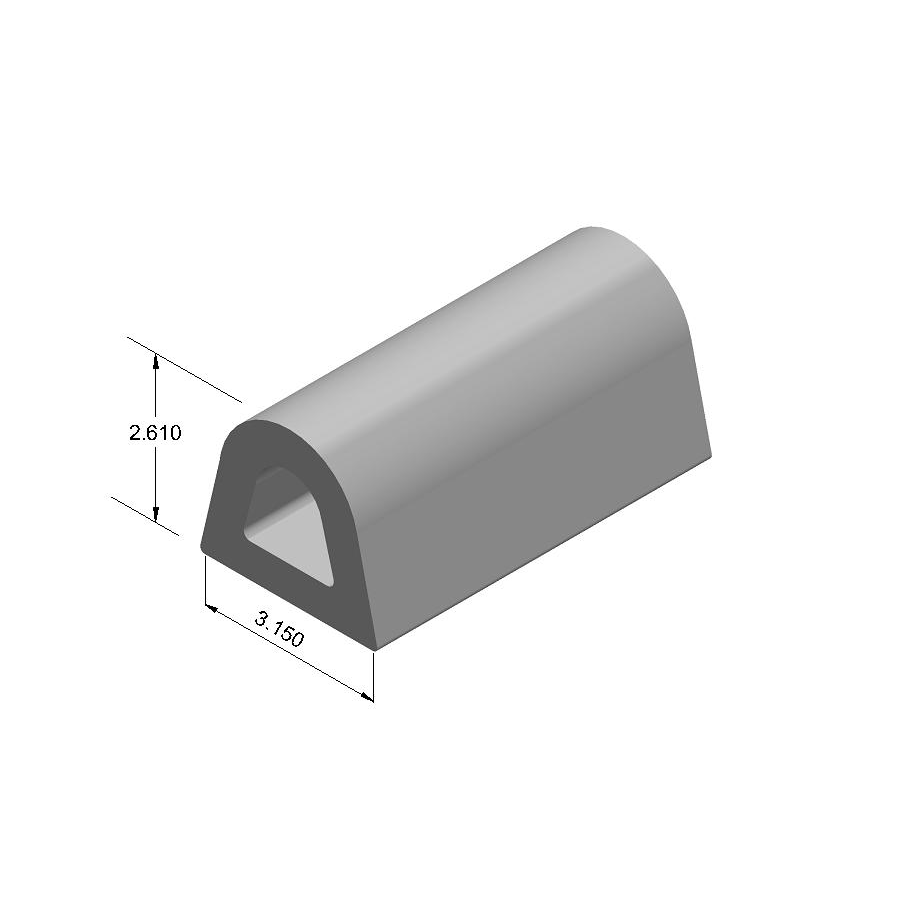

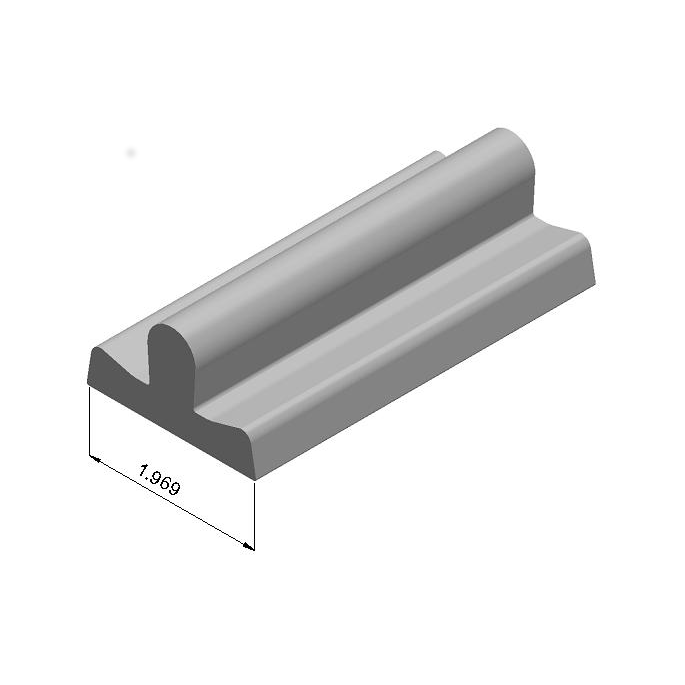

D-Type Fender

D fenders are one of the most popular Fender styles used around the world. D Type Fenders are manufactured through a process called extrusion. The D-Type Fender style is available in a wide range of designs and sizes, and is also customizable, based on the client’s specific needs. The “D” shape provides excellent impact resistance and the large, flat surface on the back of the Fender allows for straightforward installation on flat surfaces by mounting Fenders / Bumpers using Large Bolts, Nuts, and Washers. Most of our D Type Fenders / Bumpers are available pre-drilled for a nominal fee for clients that prefer a turnkey solution.

2 Standard types of Fenders available include:

- D Shape outer shape with a D shaped inner chamber. The inner chamber can be adjusted to meet client requirements.

- Solid D Shape with no hold in the middle of the profile. This is a much heavier duty design generally used for loading bays / docks, tugboats and workboats, garage walls and concrete pilings.

Application

D fenders are traditionally installed with bolts or by using aluminum straps. D Fenders can be installed horizontally, vertically or diagonally. Techno Rubber Industries (TRI) recommends using washers and lag bolts with nuts, which can be provided upon request. Most fenders and installed on the bow or stern. Each order can be customized to client needs. Keep in mind, all additional cuts and modifications need to be requested at the time the order is placed to ensure accurate pricing and timely production of your order.

Fresh and saltwater Ships including:

Workboats

Pontoons: Aluminum, Steel, and Fiberglass

Tug’s aka Tugboats: Deep-sea, Harbour & River Tug’s, Fishtug’s

Pilot Boats

Fishing Boats

Pontoons

Shipping Quays

Coast Guard, Naval, and Military ships

Docks and Marinas including

piers

loading bays

car parks trucks

Commercial

Parking Garages

Loading Docks

Building walls, Concrete Piers

Freight Trucks and Trains

Building Interiors